Carbon-Nanotube Based 3D Scaffold for Gas Absorption and Catalysts

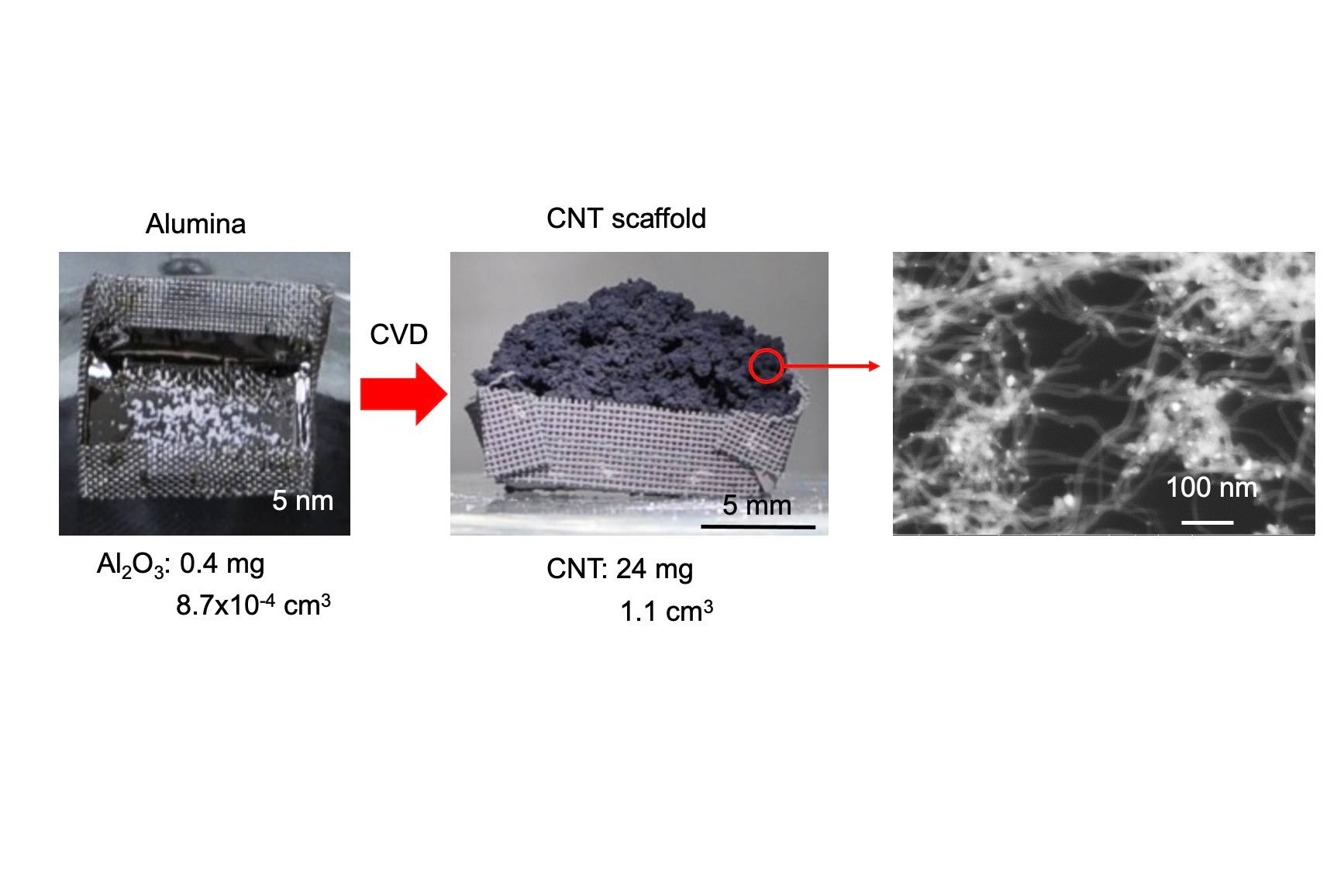

Tsung-Cheng Shen, a researcher at Utah State University, has invented another way to create carbon nanotubes (CNTs). CNTs are incredibly strong formations (more than 100 times stronger than steel) and very thin and lightweight. CNTs are grown on micron-sized alumina particles to create three-dimensional scaffolds. The scaffold volume could increase more than 100 times comparing to that of the original alumina particles. The inventor predicts the light weight and high surface area of the CNTs can be functionalized to present a unique and versatile 3D solid support for gas adsorption and catalyzing gas-phase chemical reactions. The large void of the scaffold provides low-resistance gas transport to enhance flow and reactions.

The purpose of this invention is to capture CO2 from the flue gases of power plants and mobile sources, such as household furnaces and airplanes, to reduce CO2 emissions. Solid adsorbents can reduce the energy cost for solvent regeneration in the current web-scrubbing technology. Additionally, this adsorbent can be designed for large-scale air CO2 capture which is the only way to reduce existing CO2 level in the atmosphere. Catalysis applications can be achieved by impregnating metal catalyst particles on the sidewalls of CNTs to enhance various gas-phase chemical reactions including converting CO2 to useful chemicals.

Benefits

This methods provides more pathways so the entire surface of the CNTs can be used. Using this method, micron-sized alumina particles grow CNT forests and allow CNTs to network with alumina particles to form a 3D scaffold, which is especially useful for heterogenous catalysis and gas absorption.

Applications

The main customer for this product would likely be research organizations that are interested in studying the applications of CNTs. This specific design of CNTs could be used to remove CO2 from the atmosphere, so environmental research organizations or government agencies might be interested in applying this technology.

Contact

Questions about this technology including licensing availability can be directed to:

Alan Edwards, MA, JD

Manager, Technology Transfer Services

(435) 797-2328 alan.edwards@usu.edu

USU ID C17015

Development Stage

TRL 4